1. Overview

Melt-blown nonwovens are mainly used as composite materials, filter materials, insulation materials, sanitary products, oil-absorbing materials and clean cloths (wipes), battery separators, etc., and are widely used in medical and health, automotive industry, filter materials, environmental protection and other fields.

Melt-blown non-woven fabrics are mainly used as medical and sanitary materials and coating materials. In addition, wiping and absorbing materials, filtering and barrier materials are also important uses of melt-blown fabrics.

2. Application of meltblown fabric

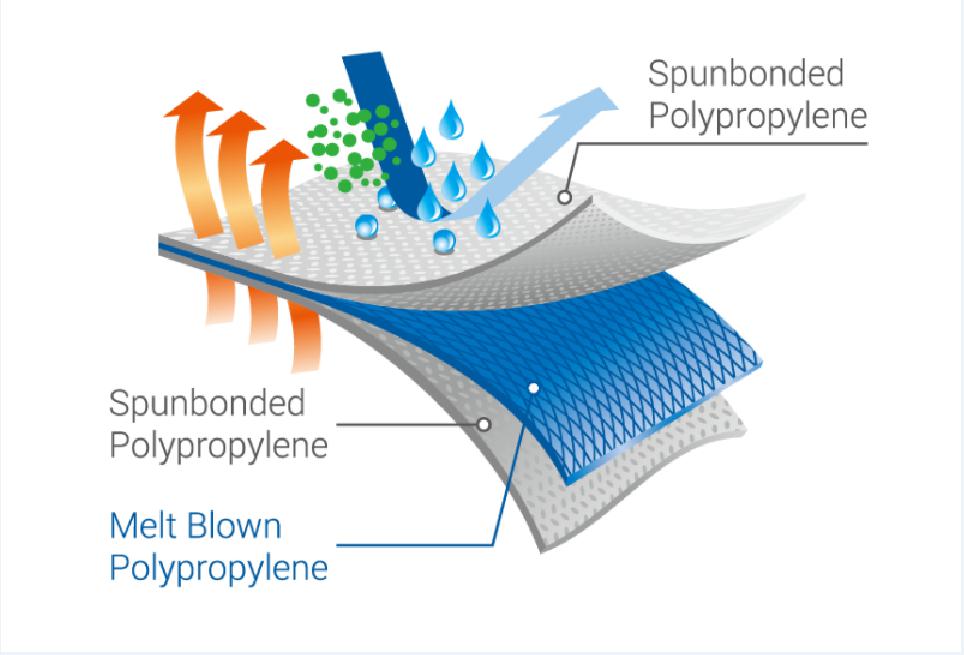

The melt blown cloth is made of polypropylene as the main raw material, and the fiber diameter can reach 0.5-10 microns. These ultra-fine fibers with a unique capillary structure increase the number and surface area of the fiber per unit area, so that the melt blown cloth has good air filtration properties. , Is a relatively good mask material. In large, medium and small medical institutions, in earthquake and flood-affected areas, and in the high incidence of SARS, avian influenza and H1N1 virus, melt blown filter paper plays an irreplaceable role with its strong filtering performance. effect.

The melt blown cloth is mainly used for:

(1) Medical and health cloths: surgical gowns, protective clothing, disinfection wraps, masks, diapers, women’s sanitary napkins, etc.;

(2) Home decoration cloth: wall cloth, table cloth, bed sheet, bedspread, etc.;

(3) Garment cloth: lining, adhesive lining, wadding, shaped cotton, various synthetic leather base cloth, etc.;

(4) Industrial cloth: filter material, insulating material, cement packaging bag, geotextile, covering cloth, etc.;

(5) Agricultural cloth: crop protection cloth, seedling raising cloth, irrigation cloth, thermal insulation curtain, etc.;

(6) Others: space cotton, thermal insulation materials, linoleum, cigarette filters, tea bags, etc.

Previous: None